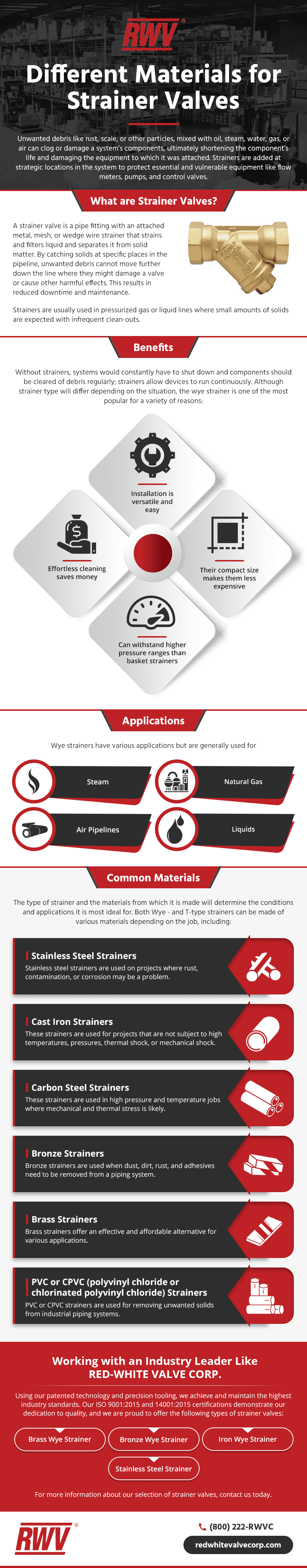

Different Materials for Strainer Valves

Comments Off on Different Materials for Strainer ValvesUnwanted debris like rust, scale, or other particles, mixed with oil, steam, water, gas, or air can clog or damage a system’s components, ultimately shortening the component’s life and damaging the equipment to which it was attached. Strainers are added at strategic locations in the system to protect essential and vulnerable equipment like flow meters, pumps, and control valves.

This article reviews the different materials for strainer valves to help you choose the right one for your application.

What are Strainer Valves?

A strainer valve is a pipe fitting with an attached metal, mesh, or wedge wire strainer that strains and filters liquid and separates it from solid matter. By catching solids at specific places in the pipeline, unwanted debris cannot move further down the line where they might damage a valve or cause other harmful effects. This results in reduced downtime and maintenance.

Strainers are usually used in pressurized gas or liquid lines where small amounts of solids are expected with infrequent clean-outs.

Strainer Valve Benefits and Applications

Without strainers, systems would constantly have to shut down and components should be cleared of debris regularly; strainers allow devices to run continuously. Although strainer type will differ depending on the situation, the Wye strainer is one of the most popular for a variety of reasons:

- Installation is versatile and easy. Wye strainers can fit either horizontally or vertically, making installation easier and more versatile.

- Their compact size makes them less expensive. Wye strainers are smaller than other strainers, meaning they are less expensive to make.

- Can withstand higher pressure ranges than basket gaskets. Wye strainers can handle pressures that might crack a basket gasket due to their shape.

- Effortless cleaning saves money. Because wye strainers are maintainable through the cap (in some cases, cleaning can be as easy as flushing through a drain), once you install one they last for a long time. This can save business owners a lot of money, as they are accessible and repairable without breaking the line.

Wye strainers have various applications but are generally used for steam, natural gas, air pipelines, and liquids.

Common Materials for Strainer Valves

The type of strainer and the materials from which it is made will determine the conditions and applications it is most ideal for. Both Wye and T-type strainers can be made of various materials depending on the job, including:

- Stainless steel strainers. Stainless steel strainers are used on projects where rust, contamination, or corrosion may be a problem.

- Cast iron strainers. These strainers are used for projects that are not subject to high temperatures, pressures, thermal shock, or mechanical shock.

- Carbon steel strainers. These strainers are used in high-pressure and temperature jobs where mechanical and thermal stress is likely.

- Bronze strainers. Bronze strainers are used when dust, dirt, rust, and adhesives need to be removed from a piping system.

- Brass strainers. Brass strainers offer an effective and affordable alternative for various applications.

- PVC or CPVC (polyvinyl chloride or chlorinated polyvinyl chloride) strainers. PVC or CPVC strainers are used for removing unwanted solids from industrial piping systems.

Working with an Industry Leader Like RED-WHITE VALVE CORP.

RED-WHITE VALVE CORP. is an industry leader in the plumbing, industrial, commercial, and HVAC markets. With over 50 years of experience, we provide world-class service and offer competitive prices for our products. Using our patented technology and precision tooling, we achieve and maintain the highest industry standards. Our ISO 9001:2015 and 14001:2015 certifications demonstrate our dedication to quality, and we are proud to offer the following types of strainer valves:

- Brass Wye Strainer

- Bronze Wye Strainer

- Iron Wye Strainer

- Stainless Steel Strainer

For more information about our selection of strainer valves, contact us today.

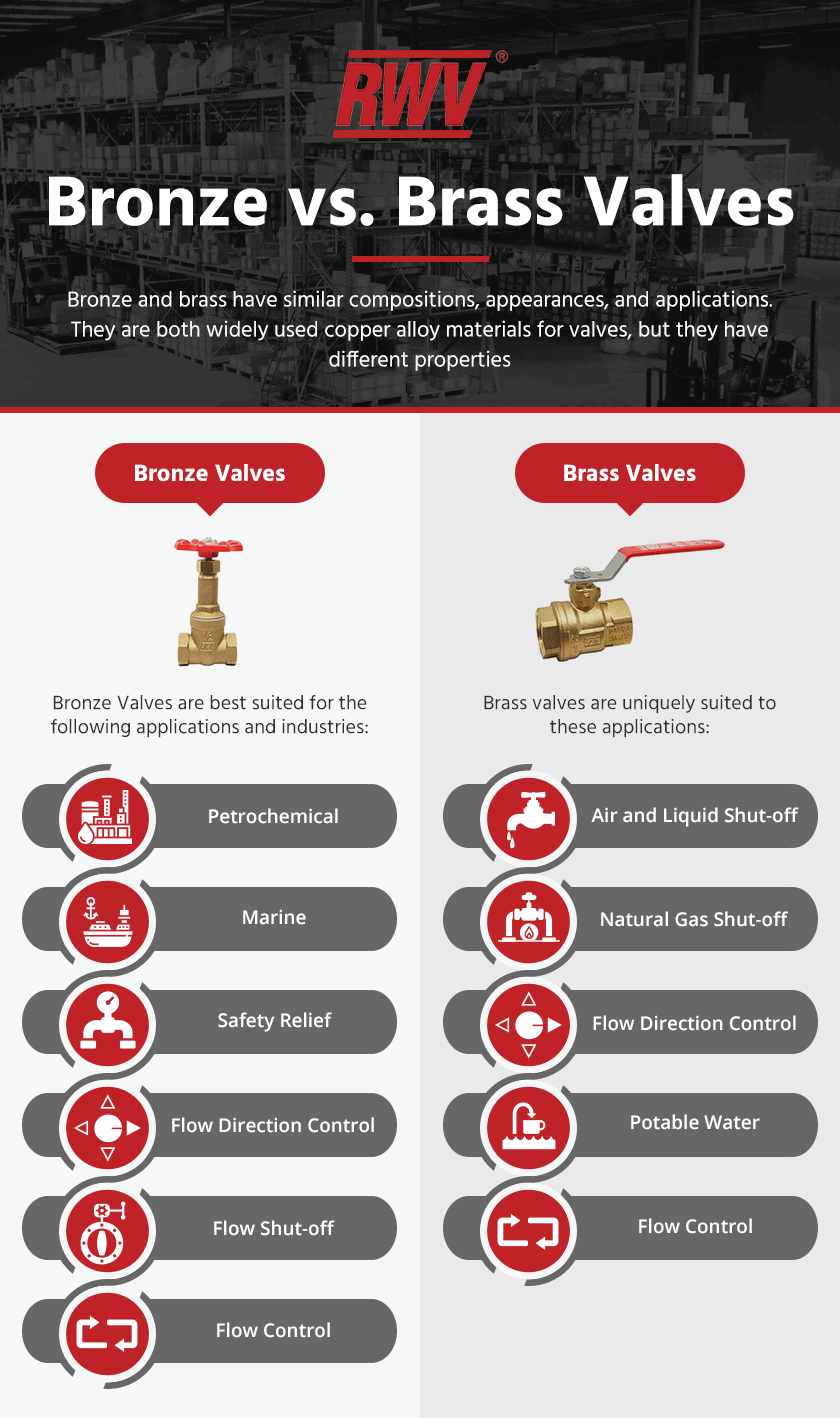

Bronze vs. Brass Valves

Comments Off on Bronze vs. Brass ValvesBronze and brass have similar compositions, appearances, and applications. They are both widely used copper alloy materials for valves, but they have different properties and price points. We’ll discuss these properties in more detail here, as well as their specific applications and advantages.

Bronze Valves

Bronze valves date back to the Romans during the first century B.C. Today, bronze is still primarily made from copper and tin, but modern additives typically include aluminum or manganese. Some bronze alloys can hold a polish if they contain nickel or lead, but generally bronze has a rough, porous finish.

Bronze valves can only be made by mold casting or machining cast ingots.

Brass Valves

Brass is a copper and zinc alloy. Brass valves are more versatile and malleable than bronze, and they can be made through casting, heat extrusion, forging, or cold drawing. The material naturally has a smooth finish that can save on finishing costs.

Brass is extremely corrosion-resistant, but prolonged exposure to chlorine or water can break down the zinc in the metal. Valves made of brass are ideal for natural gas and potable water applications.

Applications of Bronze Valves vs Brass Valves

Because of their specific properties, bronze valves are best suited for the following applications and industries:

- Petrochemical

- Marine

- Safety relief

- Flow direction control

- Flow shut-off

- Flow Control

Brass valves are uniquely suited to these applications:

- Air and liquid shut-off

- Natural gas shut-off

- Flow direction control

- Potable water

- Flow Control

Advantages of DZR Brass vs. Yellow Brass Valves

DZR brass, or dezincification-resistant brass, refers to brass with particular elements that resist the removal of zinc by water. With non-DZR brass, continuous water flow could leave behind a weak and porous copper structure. DZR brass is ideal for pipes, fittings, and valves for potable water, or high-pressure water situations, such as waterworks.

DZR brass is formulated through a heat treatment process to resist dezincification and increase strength. In contrast, ordinary yellow brass water valves can corrode quickly. They are generally cheaper and easier to machine.. DZR brass valves are superior because of their higher copper content and lower lead and zinc content. The longevity benefits of DZR brass far outweigh any financial savings from using yellow brass valves.

Valves from RED-WHITE VALVE CORP.

With these properties of brass and bronze valves in mind, you can make a more informed decision for your valve application. RED-WHITE VALVE CORP. has provided top-notch service to the plumbing, commercial, HVAC, and industrial markets since 1971. We offer a vast selection of products, including standard valves and lead-free valves. Contact us for information or to start your project.