Butterfly Valve Benefits

For many applications, the simple design of butterfly valves translates to impressive performance benefits. Some key advantages include:

-

Affordability

Affordability

With their simple design, these valves are economical to manufacture, install, and maintain.

-

Easy Rotational Motion

Easy Rotational Motion

Since they rotate easily, they can be activated quickly for reliable performance.

-

Lightweight And Space-Saving

Lightweight And Space-Saving

Butterfly valves are lightweight, and their small footprint reduces the need for piping support. This also eliminates the need for special installation equipment and reduces labor costs.

-

Superior Sealing Capabilities

Superior Sealing Capabilities

Butterfly valves achieve a tight, reliable seal, even in heavy-duty applications.

-

Versatility

Versatility

Butterfly valves are suitable for many environments, including underground usage.

Common Industrial Applications

Many industries require butterfly valves for their space-saving, reliable performance. Some of the most common industrial applications include:

-

HVAC Systems

Butterfly valves offer precise control over water flow within air handling units, chillers, and cooling towers.

-

Chemical Processing

They control the flow of hazardous chemicals and flammable liquids, including applications that require a regulated flow of substances for precise dosing.

-

Plumbing

They provide reliable water shut-off, prevent backflow, and adjust water pressure.

-

Pulp And Paper

Butterfly valves control the flow of water, steam, and corrosive substances involved in paper production.

-

Power Generation

Butterfly valves regulate liquids and gases during various stages of energy generation. They are used in nuclear, thermal, and renewable power plants to control the intake of water to turbines, manage flue gas flow, and more.

-

Oil And Gas

Butterfly valves are used as isolation valves in pipelines to prevent fluids from flowing into certain areas.

-

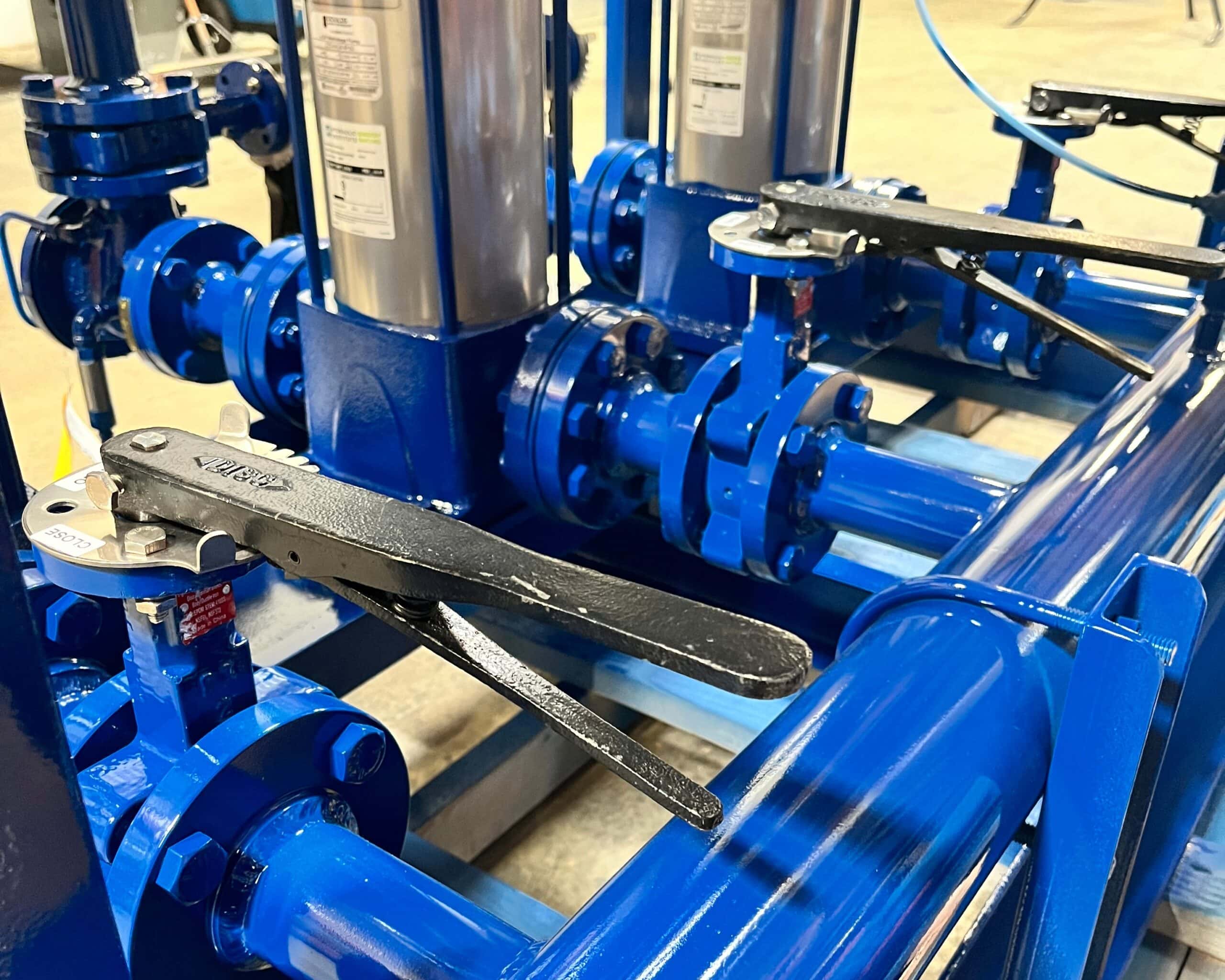

Water And Wastewater Treatment

Within sewage networks and water supply treatment systems, these valves facilitate filtration, disinfection, and sedimentation processes.

Selecting The Best Butterfly Valve Type For Your Application

Butterfly valves are categorized into two types: wafer-style and lug-style. These designs are not interchangeable, and each type is suitable for specific applications.

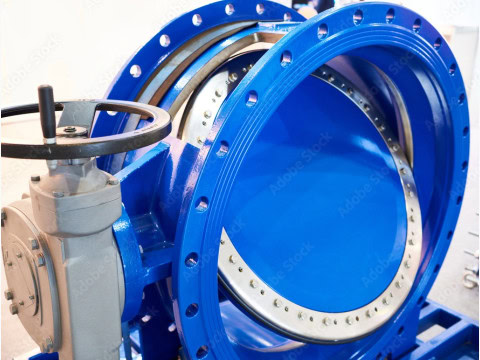

Wafer-Style Butterfly Valves

This type of butterfly valve features an external four-hole design that aligns with the connected pipe. The valve must be clamped between two flanges in the piping system, creating an exceptionally strong seal. They cannot be used for end-of- line service or as pipe ends but are compatible with electric and pneumatic actuation.

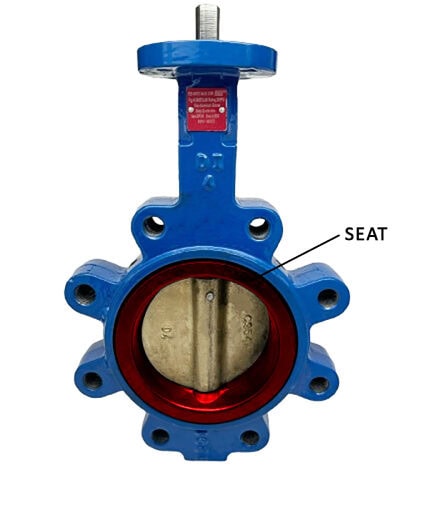

Lug-Style Butterfly Valves

Lug-style valves can be used in end-of-line service applications, however a blind flange is sometimes needed. They feature threaded tapped lugs on the flanges for bolt connections and are compatible with either electric or pneumatic actuation. Their larger size can make them more challenging to install in space-constrained settings. Lug-style butterfly valves are commonly used in water treatment, process control, and paper production applications.

Butterfly Valve Parts

Both butterfly valve types feature simple designs comprised of the same basic parts:

Exploring Butterfly Valve Design Options

Custom butterfly valve design options can satisfy a wide range of installation and functional requirements. Select from various disc closure, pipe connection, and actuation methods depending on your application’s needs.