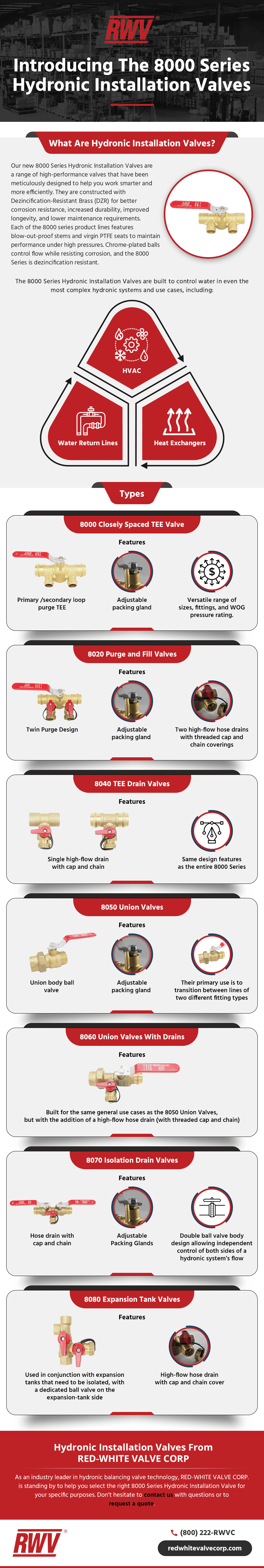

What Are Hydronic Installation Valves?

Our 8000 series hydronic installation valves are a range of high-performance valves that have been meticulously designed to help you work smarter and more efficiently. These valves are engineered to be the perfect solution for professionals who want to streamline their workflow and save time. They function as the final control element for hydronic systems, evenly distributing chilled or heated water to the terminals regardless of fluctuating system conditions.

A key distinguishing characteristic of our 8000 series valves is their capacity to predict the future requirements of the systems or devices they serve. We understand that maintenance and repairs can be a significant headache, which is why we have incorporated built-in valves and drains into our product line. These features make it much easier to isolate and service the valve, reducing downtime and minimizing the impact on your productivity.

Our new 8000 Series Hydronic Installation Valves are constructed with Dezincification-Resistant Brass (DZR) for better corrosion resistance, increased durability, improved longevity, and lower maintenance requirements. Each of the 8000 series product lines features blow-out-proof stems and virgin PTFE seats to maintain performance under high pressures. Chrome-plated balls control flow while resisting corrosion, and the 8000 Series is dezincification resistant.

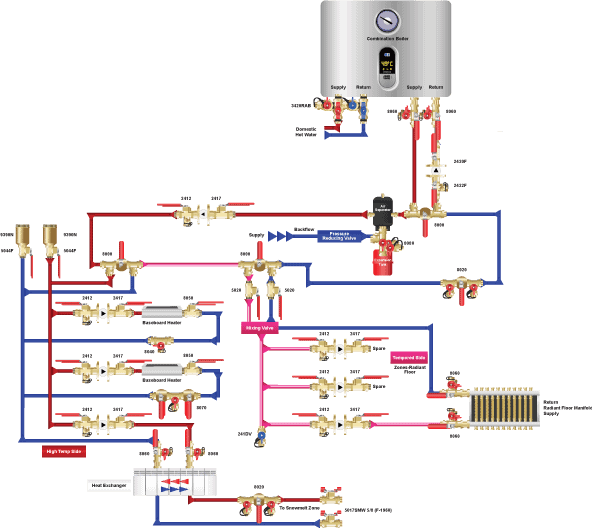

The 8000 Series Hydronic Installation Valves are built to control water in even the most complex hydronic systems and use cases, including:

- HVAC

- Heat exchangers

- Water return lines

8000 Closely Spaced TEE Valves

In addition to the standard 8000 Hydronic Installation Valve design features, the 8000 Closely Spaced TEE Valves feature adjustable packing glands for maximum seal. They also have a versatile range of sizes, fittings, and WOG pressure ratings.

8000P

- EzPress connections

- Rated for up to 250 WOG

8000S

- Solder connections

- Rated for up to 600 WOG

8000E

- PEX ASTM F1960 connections

- Rated for up to 400 WOG

The 8000P, 8000S, and 8000E hydronic balancing valves come in the following sizes:

- 1″ x 1″ x ¾”

- 1″ x 1″ x 1″

- 1-¼” x 1-¼” x ¾”

- 1-¼” x 1-¼” x 1″

8020 Purge and Fill Valves

In addition to the adjustable packing gland and standard design/safety features of the 8000 series, the 8020 Purge and Fill Valves feature two high-flow hose drains with threaded cap and chain coverings.

8020P

- EzPress connections

- Rated for up to 250 WOG

- ¾” x Male hose

- 1″ x Male hose

- 1-¼” x Male hose

8020S

- Solder connections

- Rated for up to 600 WOG

- ¾” x Male hose

- 1″ x Male hose

- 1-¼” x Male hose

8040 TEE Drain Valves

The 8040 TEE Drain Valves feature a single high-flow drain with cap and chain, an adjustable packing gland, and the same design features as the entire 8000 Series.

8040P

- EzPress connections

- Rated for up to 250 WOG

- ½” – 1-¼”

8040S

- Solder connections

- Rated for up to 600 WOG

- ½” – 1-¼”

8050 Union Valves

The 8050 Union Valves feature a union body ball valve in addition to an adjustable packing gland. Their primary use is to transition between lines of two different fitting types.

8050P-PF

- EzPress x FNPT

- Rated for up to 250 WOG

- ¾” thru 1-1/4″

8050S-SF

- Solder x FNPT

- Rated for up to 600 WOG

- ¾” thru 1-1/4″

8050T-FF

- FNPT x FNPT

- Rated for up to 600 WOG

- ¾” thru 1-1/4″

8060 Union Valves With Drains

The 8060 Union Valves are built for the same general use cases as the 8050 Union Valves, but with the addition of a high-flow hose drain (with threaded cap and chain).

8060P-PF

- EzPress x FNPT

- Rated for up to 250 WOG

- ¾” thru 1-1/4″

8060S-SF

- Solder x FNPT

- Rated for up to 600 WOG

- ¾” thru 1-1/4″

8060T-FF

- FNPT x FNPT

- Rated for up to 600 WOG

- ¾” thru 1-1/4″

8070 Isolation Drain Valves

With a double ball valve body design, the 8070 Isolation Drain Valves allow independent control of both sides of a hydronic system’s flow. They feature an adjustable packing gland and a hose drain with cap and chain.

8070P

- EzPress connections

- Rated for up to 250 WOG

- ¾” thru 1-1/4″

8070S-SF

- Solder connections

- Rated for up to 600 WOG

- ¾” thru 1-1/4″

8070T-FF

- FNPT connections

- Rated for up to 600 WOG

- ¾” thru 1-1/4″

8080 Expansion Tank Valves

The 8080 Expansion Tank Valves are used in conjunction with expansion tanks that need to be isolated, with a dedicated ball valve on the expansion-tank side. They also feature a high-flow hose drain and a cap and chain cover.

8080MT

- MNPT system connection

- Rated for up to 600 WOG

- ½”

8080FT

- FNPT system connection

- Rated for up to 600 WOG

- ½”

Hydronic Installation Valves From RED-WHITE VALVE CORP.

When selecting a hydronic balancing valve, the entire hydronic system must be taken into account. Matching a hydronic balancing valve to your exact system must be done according to coil sizing, coil response curves, piping losses, balancing, and other factors.

As an industry leader in hydronic balancing valve technology, RED-WHITE VALVE CORP. is standing by to help you select the right 8000 Series Hydronic Installation Valve for your specific purposes. Don’t hesitate to contact us with questions or to request a quote.