Industrial valves are mechanical devices that open, close, or partially obstruct passageways to regulate the flow of liquid or gas within a system. With the variety of valve options on the market, finding the one that will provide optimal results in your specific application can be challenging. Having a general understanding of the different valve designs available and how they support specific processing or fluid handling applications is an important first step in the selection process.

Types of Industrial Valves

While they all provide similar functions, industrial valves have evolved into various types with specialized designs and features to meet a number of application-specific requirements. The main types of valves available and their ideal uses are explored below.

Balancing Valve

Balancing valves are designed to control flow throughout a system by regulating the flow among multiple flow branches. These valves perform several critical functions in HVAC systems and fluid power applications. In commercial heating and cooling systems, for example, balancing valves enable adjustments to GPM under varying loading conditions. They can also be used to balance the load of double-acting cylinders by providing a counterbalancing force.

Ball Valve

A ball valve is a quarter-turn valve that starts or stops the flow of fluids using a hollow, ball-shaped insert. The valve can be quickly opened or closed with a 90-degree turn of the valve handle. With their relatively simple designs, ball valves are low-maintenance, long-lasting, and exhibit minimal leakage if used properly.

A ball valve is a quarter-turn valve that starts or stops the flow of fluids using a hollow, ball-shaped insert. The valve can be quickly opened or closed with a 90-degree turn of the valve handle. With their relatively simple designs, ball valves are low-maintenance, long-lasting, and exhibit minimal leakage if used properly.

These valves are commonly used in fluid, gaseous, and vapor applications that require bubble-tight shut-offs. Although they are mostly used for low-pressure applications, ball valves with metal seats are suitable for high-pressure, high-temperature uses.

Types of industrial ball valves include:

- CSA Gas Ball Valve: A gas ball valve is a specialized type of ball valve that requires a CSA (Canadian Standards Association) certification to be safely used in combustible gas applications. Valves that are CSA-certified have undergone rigorous quality testing according to measures put in place under U.S. law as well as other independent organizations (UL, ANSI, NSF, etc.).

- EzPress/EzGrip Ball Valve: EzPress and EzGrip ball valves are ergonomically designed to enable easy and quick activation or deactivation in industrial applications. These valve connections are designed to save time and money during installation.

- PEX valves: PEX valves are two-way, full-port quarter-turn valves that are most often used for shutting off water supply to plumbing fixtures and other appliances during repair or maintenance services. F-1960, F-1807 and Everloc + are the most common types of pex connections.

- PP-R valves: PP-R valves are designed to be compatible with PP-R pipes, which are straight and rigid cylindrical pipes used to transfer various fluids in industrial applications. The polypropylene composition of PP-R pipes and valves makes them highly resistant to aggressive chemicals and abrasive particles. This system uses heat welding as well as electrofusion to make socket and butt-weld connections.

Butterfly Valve

A butterfly valve is a quarter-turn valve with a rotating metal disc that is positioned perpendicular to the stream of fluid when closed. Intermediate rotations of the disc allow for precise regulation of the amount of liquid flowing through a system. They are offered in wafer or lug style variations. Their high accuracy and reliability make them well-suited for a number of industrial applications, including:

- Water supply

- Wastewater treatment

- Fluid-handling power applications

- Pharmaceutical, chemical, and food processing services

Gate Valve

Gate valves are designed primarily for blocking flow rather than regulating it. They contain a plate-like barrier (gate) that can be inserted into the stream of a fluid to block its flow. Gate valves share some operational similarities with globe valves, but they provide less flow restriction when in the fully opened position.

Because of this unobstructed flow path, gate valves have significantly reduced head loss when compared with globe valves. However, gate valves are not designed for throttling purposes and may not be capable of producing the positive shut-off that is provided by globe valves. Gate valves are most often used to provide shut-off or isolating capabilities in wastewater plants, power plants, and process plants.

Globe Valve

A globe valve is a linear motion valve that uses a globe-shaped disc to stop, start, or regulate flow in pipelines. The movable disc, also referred to as a plug, can be closed against a stationary ring seat to constrict flow. To control disc movement, manually operated globe valves rely on handwheels, while automatic globe valves use actuators and sliding shafts.

A globe valve is a linear motion valve that uses a globe-shaped disc to stop, start, or regulate flow in pipelines. The movable disc, also referred to as a plug, can be closed against a stationary ring seat to constrict flow. To control disc movement, manually operated globe valves rely on handwheels, while automatic globe valves use actuators and sliding shafts.

Globe valves tend to be more leak-proof than other valves and provide a shorter opening-closing time. These general-purpose valves are primarily used for shut-off and regulation in high-temperature applications such as wastewater plants, process plants, and food processing plants.

Check Valve

Check valves are automatic one-way valves that are designed to allow fluid flow in one direction only. These valves are used in pumps, gas lines, HVAC systems, and other applications requiring one-way fluid movement. Types of check valves include:

Check valves are automatic one-way valves that are designed to allow fluid flow in one direction only. These valves are used in pumps, gas lines, HVAC systems, and other applications requiring one-way fluid movement. Types of check valves include:

- Lift-type check valve: With lift-type check valves, a ball or piston opens under a specified pressure to allow fluid flow. A decrease in pressure will force the piston or ball into the valve seat, thus closing the valve and preventing backflow.

- Swing check valve: A swing check valve relies on a hinged disc that swings away from the valve seat to permit flow in the forward direction. If the upstream flow stops, the disc returns to the valve seat to prevent backflow.

- Butterfly check valve: Butterfly check valves consist of two half-circle gates hinged together. Forward flow pushes the gates open, while reverse flow causes them to retract.

Industrial Valve Applications

Click to Zoom

Click to Zoom

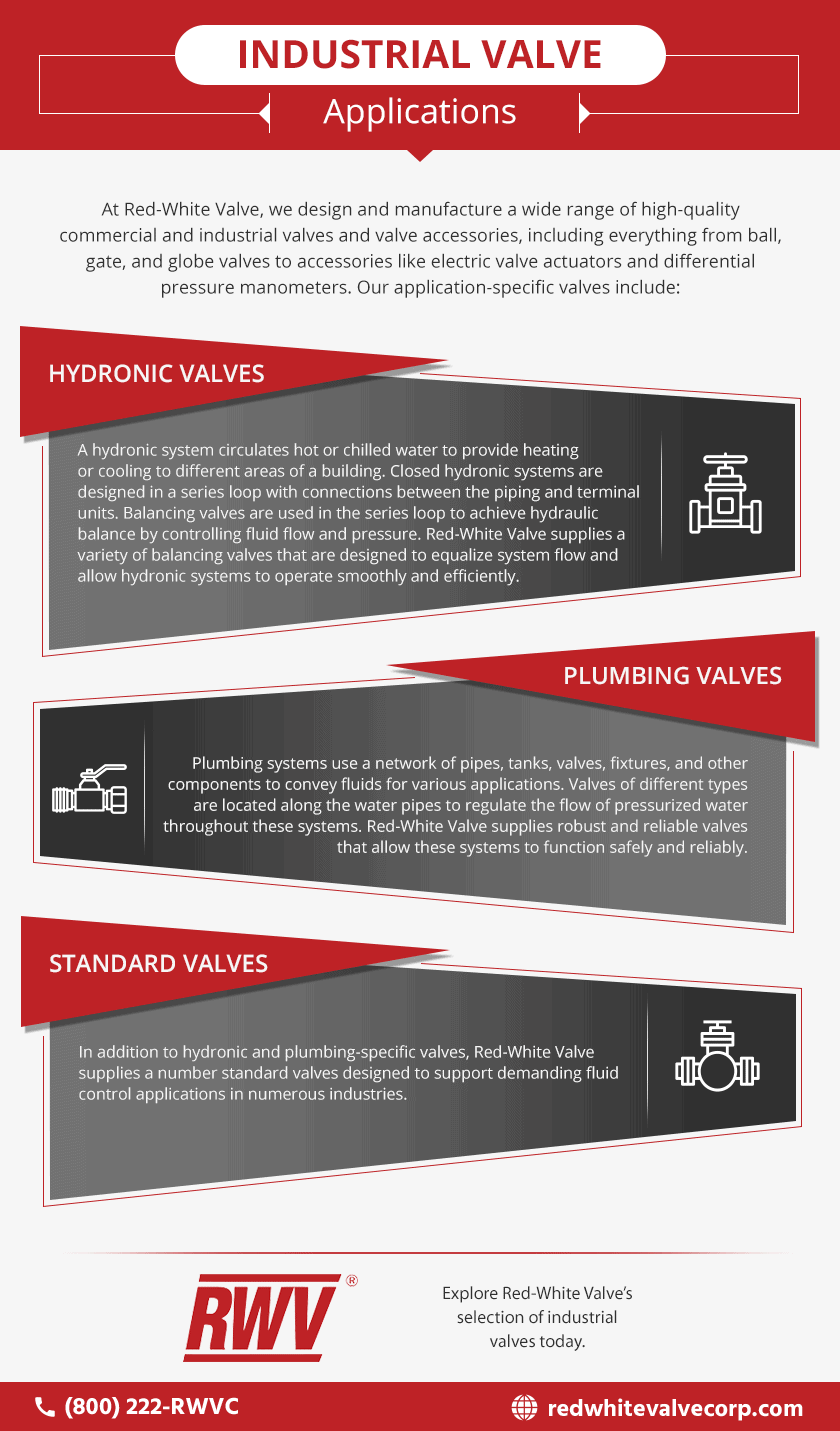

At RED-WHITE VALVE CORP., we design and manufacture a wide range of high-quality commercial and industrial valves and valve accessories, including everything from ball, gate, and globe valves to accessories like electric valve actuators and differential pressure manometers. Our application-specific valves include:

- Hydronic valve: A hydronic system circulates hot or chilled water to provide heating or cooling to different areas of a building. Closed hydronic systems are designed in a series loop with connections between the piping and terminal units. Balancing valves are used in the series loop to achieve hydraulic balance by controlling fluid flow and pressure. RED-WHITE VALVE CORP. supplies a variety of balancing valves that are designed to equalize system flow and allow hydronic systems to operate smoothly and efficiently.

- Plumbing valve: Plumbing systems use a network of pipes, tanks, valves, fixtures, and other components to convey fluids for various applications. Valves of different types are located along the water pipes to regulate the flow of pressurized water throughout these systems. RED-WHITE VALVE CORP. supplies robust and reliable valves that allow these systems to function safely and reliably.

- Standard valve: In addition to hydronic and plumbing-specific valves, RED-WHITE VALVE CORP. supplies a number standard valves designed to support demanding fluid control applications in numerous industries.

Trust RED-WHITE VALVE CORP. for Your Next Project

When it comes to industrial fluid handling applications, choosing the right valve is essential for establishing and maintaining a well-functioning, efficiently-operating system. With nearly 50 years of experience in our industry, RED-WHITE VALVE CORP. has the in-depth knowledge and extensive resources to manufacture and supply expertly designed valves for various plumbing, commercial, industrial, and HVAC applications.

Part of our success comes from our ability to manufacture our valves completely in-house, giving us the control needed to ensure that each product is constructed and tested according to the highest industry standards. We also take the time to fully listen to and understand the needs of our customers so that we can deliver carefully targeted products and services for each unique application. With 8 warehouses distributed throughout North America, we can ensure that our customers always have access to the products they need.

For valve selection assistance or to learn more about any of our products, please contact us today.