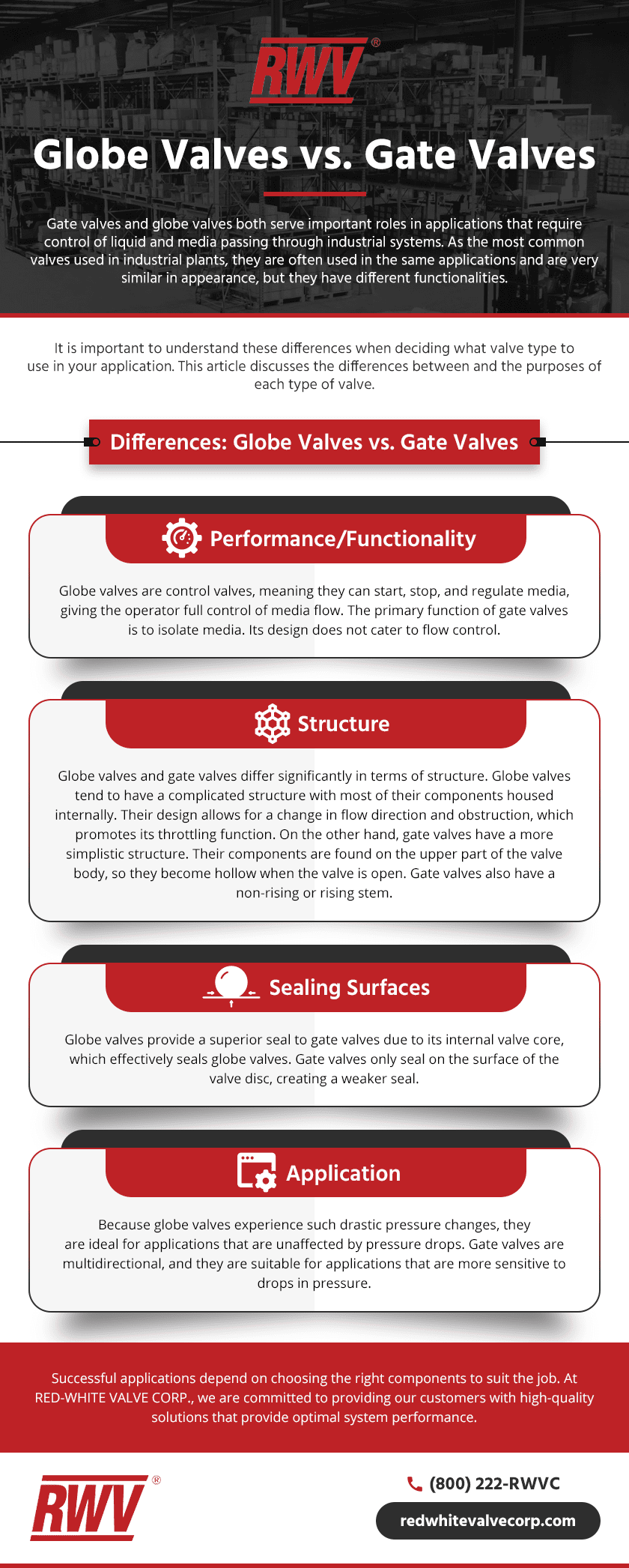

Globe Valves vs. Gate Valves

Comments Off on Globe Valves vs. Gate ValvesGate valves and globe valves both serve important roles in applications that require control of liquid and media passing through industrial systems. As the most common valves used in industrial plants, they are often used in the same applications and are very similar in appearance, but they have different functionalities.

It is important to understand these differences when deciding what valve type to use in your application. This article discusses the differences between and the purposes of each type of valve.

Globe Valves

At a glance, it is easy to understand why globe valves were named as such. Traditional globe valves closely resemble a globe. Belonging to the linear motion valve family, globe valves are primarily intended to start, stop, and regulate the flow of media. Most globe valves have a top-entry design, meaning you have to access the valve’s internal components from the top.

Globe valves provide a tight, efficient seal to limit the risk of leakage. They are suitable throttling valves because their seats are parallel to the media flow, preventing erosion of the seat when the valve is on. Globe valves experience high-pressure drops and are more resistant to media flow when the valve is turned on.

Applications that encounter high temperatures, high pressures, or highly viscous media call for globe valves. They are appropriate for applications that require a safe, leak-proof solution that resists corrosion. Due to their capabilities, globe valves are more costly than gate valves but are a worthwhile expense in certain applications.

Gate Valves

As part of the shutoff valve family, these linear valves feature a wedge-shaped gate and a rising or non-rising stem to indicate when the valve is open or closed. The primary function of gate valves is to isolate media by providing a tight seal to stop the flow. Unlike globe valves, they don’t regulate the flow of media, but they can accommodate any flow direction.

Gate valves are ideal for applications that require tight sealing. Knife valves, a unique variety of gate valves, are suitable for viscous media. Gate valves are useful in wide variety of above- and below-ground applications and are suitable for all kinds of fluids, including gas and water.

Differences: Globe Valves vs. Gate Valves

While they appear similar in design and can be used in similar ways, these two valves differ in functionality, structure, sealing capabilities, and application.

Some of the most distinct differences between globe valves and gate valves include the following:

- Performance/Functionality: Globe valves are control valves, meaning they can start, stop, and regulate media, giving the operator full control media flow. The primary function of gate valves is to isolate media. Its design does not cater to flow control.

- Structure: Globe valves and gate valves differ significantly in terms of structure. Globe valves tend to have a complicated structure with most of their components housed internally. Their design allows for a change in flow direction and obstruction, which promotes its throttling function. On the other hand, gate valves have a more simplistic structure. Their components are found on the upper part of the valve body, so they become hollow when the valve is open. Gate valves also have a non-rising or rising stem.

- Sealing surfaces: Globe valves provide a superior seal to gate valves due to its internal valve core, which effectively seals globe valves. Gate valves only seal on the surface of the valve disc, creating a weaker seal.

- Application: Because globe valves experience such drastic pressure changes, they are ideal for application that are unaffected by pressure drops. Gate valves are multidirectional, and they are suitable for applications that are more sensitive to drops in pressure.

Valve Solutions at RED-WHITE VALVE CORP.

Successful applications depend on choosing the right components to suit the job. At RED-WHITE VALVE CORP., we are committed to providing our customers with high-quality solutions that provide optimal system performance.

With over 50 years serving the commercial, industrial, HVAC, and plumbing industries, we have the expertise to help you find the right solution for your business. To learn more about our selection of globe and gate valves, contact us or request a quote today.

How to Maintain a Gas Tankless Water Heater

Comments Off on How to Maintain a Gas Tankless Water HeaterGas tankless water heaters offer an energy-efficient and cost-effective way to get hot water on demand. However, these systems require proper maintenance to prevent premature component failure and ensure long service life. Generally, tankless water heaters should be serviced once a year; however, they may require more frequent maintenance if you have hard water or if you keep your water temperature high. To ensure that your tankless water heater is properly maintained, there are many steps you can take.

What is a Tankless Water Heater?

Tankless water heaters are a type of on-demand water heater that provides hot water when needed. They are capable of heating water without the need for a storage tank. Once a hot water faucet is turned on, cold water moves through the unit’s heat exchanger before it is heated by a natural gas burner. This results in a constant supply of hot water without having to wait for a storage tank to fill.

Some of the primary advantages of gas tankless water heaters are their energy efficiency and compact size. This means that these systems not only save money but also save on the amount of space they take up in an area. However, minerals can build up within the heat exchanger over time, which can cause clogs and affect the water flow speed. Because of this, tankless water heaters require a certain degree of maintenance to ensure optimal performance.

Steps for Maintaining a Tankless Water Heater

When performing maintenance on your gas tankless water heater, it’s important to follow these steps:

All tankless water heaters are not alike and therefore, cleaning procedures may differ. Always refer to the manufacturer’s recommendations on proper cleaning procedures.

1. Turn Off The Energy Source

To ensure optimal safety, it is crucial to turn off the energy source before performing inspection or maintenance. In the case of a gas tankless water heater, you will need to turn off the main gas supply valve.

2. Close All Main Water Valves

To prevent water from entering the water heater, you must close the main water valves. Typically, there is a blue valve that marks cold water (in) and a red valve that marks hot water (out).

3. Remove Purge Port Valve Caps

Purge port valve caps cover and protect the hose connections used for maintenance.

4. Attach Hoses To Each Valve

Connect hoses to the hot and cold purge ports. The hose connected to the cold valve (blue) will attach to a small recirculation pump. The hose connected to the hot valve (red) will feed back to the cleaning solution container.

5. Open the Port Valves

Open all the port valves by turning them perpendicular to the direction of the water lines.

6. Descale

To thoroughly clean your tankless water heater, use a commercial descaling solution or white vinegar mixture to the container. The recirculation pump should be submerged in the cleaning fluid container. Turn on the pump. The pump will push the cleaning fluid through the hose and into the heat exchanger. The fluid will then exit the heater and return to the cleaning fluid container.

(Note: some manufacturers require the electrical power to be on during this procedure to allow all internal actuated valves to open properly)

7. Flush and Drain the Unit

To complete your maintenance routine, simply flush and drain your tankless water heater for approximately 45-60 minutes for thorough cleaning. Now, you can close the port valves, disconnect the hosing, and reseal the purge valves. It is always a good idea to do a final flush with clean water to remove any cleaning solution from the unit.

Tankless Water Heater Valve Kits From RED-WHITE VALVE CORP.

At RED-WHITE VALVE CORP., we offer valve and valve kits for gas tankless water heater maintenance. To ensure that all your daily tasks run smoothly, it’s crucial to maintain proper water pressure, and maintaining your water heater’s pressure relief valves is a key step in doing this. Our water heater relief valves relieve excess pressure in your tankless water heater to prevent pressure buildup that could lead to a tank burst.

Our valve and valve kits for tankless water heater maintenance include:

- 3420RAB/TAB LF Tankless Water Heater Valve Kit. This valve kit features virgin PTFE seats, an integral base drain, a purge port V/Cap, and an integral relief valve.

- 350R/352R Tankless Contractor Kit with Gas Accessories. The 350R/352R kit includes 3400RAB or 3420RAB configurations, a gas valve, and a flexible gas connector.

- 3400AB LF Tankless Water Heater Valve Kit. This tankless water heater valve kit features a full port, virgin PTFE seats, integral base drain, purge port with cap, and an integral relief valve.

To learn more about the gas tankless water heater maintenance solutions from RED-WHITE VALVE CORP., contact us or request a quote today.

Everything You Need to Know About Ball Valves

Comments Off on Everything You Need to Know About Ball ValvesBall valves are a type of shut-off valve designed to control the flow of a gas or liquid through the use of a pivoting ball that has a port through its center. When the ball is rotated 90°, the medium is either blocked or allowed to flow through, depending on the orientation of the port. Ball valves come in a wide range of styles, materials, and sizes to meet the particular needs of various applications.

What Are Ball Valves?

Ball valves are installed throughout piping systems to allow, obstruct, and control the flow of various vapors, gases and liquids. The ball is mounted against two seats and is connected with a shaft to the control mechanism used to rotate the ball. When the port opening is perpendicular to the flow, the fluid is not allowed to pass through the valve. By rotating the port to the open position, fluid is allowed to pass through at a controlled rate.

Design

One key design element of ball valves is their construction material. Ball valves can be constructed from a wide range of materials, such as metals, plastics, or metal fused with ceramic. The ball itself is often plated with chrome for added durability. The ideal ball valve material depends on factors such as operating temperature, pressure, and the type of fluid that will move through it.

Another design aspect of ball valves is their port profile. The hole through the ball can have different profiles such as V-shaped, reduced port or full port:

- V-Shaped. A V-shaped or characterized profile allows for more precise control of flow rate by rotating the ball. The profile can be optimized to achieve linear flow characteristics.

- Reduced port. This is the most common type of bore profile. Reduced bore ball valves can introduce friction losses into a system; however, these losses are relatively small compared to other valve types.

- Full port. These ports have the same diameter as the pipe, meaning they are easier to clean and there are no extra friction losses. However, full port valves often cost more and are bigger than standard ball valves.

Function

Similar to other valves that use a rotating disc to control the movement of fluid throughout a system, ball valves use a ball to control the fluid. By moving the actuator, the ball rotates to a point where the port aligns with the valve body outlet and inlet, allowing the fluid to flow through the valve.

The valve needs a one-quarter turn of a handwheel to move from fully open to fully closed. This small degree of movement allows operators to quickly open and close the valve in the event of an emergency. By closing the valve, operators can easily isolate a section of piping for repairs, installation, or inspection.

Applications

Because of minimal flow restrictions, ball valves cause a low-pressure drop compared to other valve types, which prevents valve damage. Since ball valves only require a one-quarter turn to fully open or shut off, they offer a great way to immediately allow or restrict fluid flow. This advantage makes ball valves a popular option for a wide range of residential and specialized applications, including:

- Outdoor hoses, plumbing, washing machines, and other residential applications

- Oil and gas refining and processing applications

- Automotive production applications

- Power processing

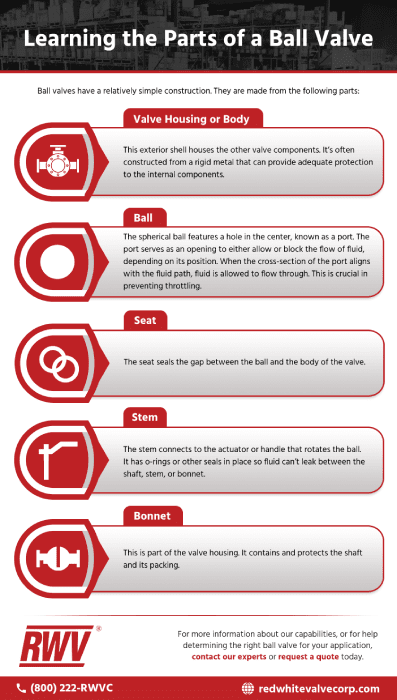

Ball Valve Parts

Valve Housing or Body

This exterior shell houses the other valve components. It’s often constructed from a rigid metal that can provide adequate protection to the internal components.

Ball

The spherical ball features a hole in the center, known as a port. The port serves as an opening to either allow or block the flow of fluid, depending on its position. When the cross-section of the port aligns with the fluid path, fluid is allowed to flow through. This is crucial in preventing throttling.

Seat

The seat seals the gap between the ball and the body of the valve.

Stem

The stem connects to the actuator or handle that rotates the ball. It has o-rings or other seals in place so fluid can’t leak between the shaft, stem, or bonnet.

Bonnet

This is part of the valve housing. It contains and protects the shaft and its packing.

Working With RED-WHITE VALVE CORP.

At RED-WHITE VALVE CORP., we specialize in creating high-quality ball valves for various residential, commercial, and industrial applications. Our products include:

For more information about our capabilities, or for help determining the right ball valve for your application, contact our experts or request a quote today.