Balancing Valves 101

Comments Off on Balancing Valves 101 Hydronic systems are HVAC systems that utilize water to heat and cool different areas of a facility.Balancing valves are valves designed to attain hydraulic balance within such systems by regulating fluid flow and pressure. When selected and installed properly, they equalize system pressure, creating comfortable thermal conditions in the building while optimizing energy and operating costs.

Hydronic systems are HVAC systems that utilize water to heat and cool different areas of a facility.Balancing valves are valves designed to attain hydraulic balance within such systems by regulating fluid flow and pressure. When selected and installed properly, they equalize system pressure, creating comfortable thermal conditions in the building while optimizing energy and operating costs.

How difficult it is to achieve balance within a hydronic system depends on the size and configuration of the system. For example, residential systems are smaller and simpler, so they are easier to balance than industrial or commercial systems, which are generally larger and more complex.

The following article provides an overview of balancing valves, including the types available and typical applications, to help customers decide which type of balancing valve is right for their needs.

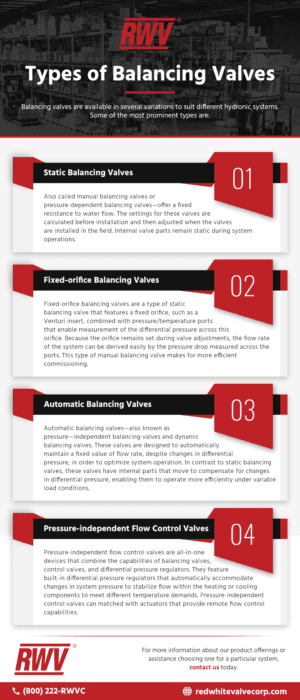

Types of Balancing Valves

Balancing valves are available in several variations to suit different hydronic systems. Some of the most prominent types are:

- Static balancing valves—also called manual balancing valves or pressure-dependent balancing valves—offer a fixed resistance to water flow. The settings for these valves are calculated before installation and then adjusted when the valves are installed in the field. Internal valve parts remain static during system operations.

- Fixed-orifice balancing valves are a type of static balancing valve that features a fixed orifice, such as a Venturi insert, combined with pressure/temperature ports that enable measurement of the differential pressure across this orifice. Because the orifice remains set during valve adjustments, the flow rate of the system can be derived easily by the pressure drop measured across the ports. This type of manual balancing valve makes for more efficient commissioning.

- Automatic balancing valves—also known as pressure-independent balancing valves and dynamic balancing valves. These valves are designed to automatically maintain a fixed value of flow rate, despite changes in differential pressure, in order to optimize system operation. In contrast to static balancing valves, these valves have internal parts that move to compensate for changes in differential pressure, enabling them to operate more efficiently under variable load conditions.

- Pressure-independent flow control valves are all-in-one devices that combine the capabilities of balancing valves, control valves, and differential pressure regulators. They feature built-in differential pressure regulators that automatically accommodate changes in system pressure to stabilize flow within the heating or cooling components to meet different temperature demands. Pressure-independent control valves can matched with actuators that provide remote flow control capabilities.

Applications of Balancing Valves

The primary use case of balancing valves is hydronic balancing. This process refers to the optimization of water distribution within a hydronic heating or cooling system by equalizing fluid pressure. Ultimately, by achieving balance within these systems, balancing valves ensure the following:

- Correct temperature levels are reached and maintained

- Energy utilization is optimized

- Operating costs are lowered

Find out how a differential pressure manometer operates.

Contact the Valve Experts at RED-WHITE VALVE CORP. Today

Balancing valves play a critical role in hydronic systems. In addition to facilitating heating and cooling operations, they help reduce energy and operating costs. As they are available in several different types, choosing the right one for a system can be difficult. For selection assistance, turn to the valve experts at RED-WHITE VALVE CORP.

At RED-WHITE VALVE CORP., we are a premier supplier of valves for the HVAC and other industrial and commercial markets. Equipped with almost 50 years of industry experience and advanced manufacturing technologies, we have the knowledge and tools to design and deliver a broad selection of quality valve products, including balancing valves. For more information about our product offerings or assistance choosing one for a particular system, contact us today.

WE ARE THE MANUFACTURER!