Electric valve actuators control the opening and closing of valves. They can provide either linear or rotary motion and work with different types of valves, including ball and butterfly valves. Electric valve actuators respond to prompts through remote control or centralized process control systems, which make them invaluable for managing systems that are hard to reach or spread across a large area. Process control systems can operate electric actuators from a centralized system to deliver scheduled and programmed commands, thereby allowing organizations to automate the system and improve reliability.

Electric valve actuators control the opening and closing of valves. They can provide either linear or rotary motion and work with different types of valves, including ball and butterfly valves. Electric valve actuators respond to prompts through remote control or centralized process control systems, which make them invaluable for managing systems that are hard to reach or spread across a large area. Process control systems can operate electric actuators from a centralized system to deliver scheduled and programmed commands, thereby allowing organizations to automate the system and improve reliability.

Overall, electric valve actuators are becoming increasingly responsive, technologically advanced, and easier to use. The following guide explains what you need to know about how these components work and what’s needed to install and use them.

Electric Actuator Components

Unlike other valve actuators, electric actuators contain motors that can convert electricity in either linear or rotary motion to open, close, or adjust a corresponding valve. Different electric actuators control various types of movement; a quarter-turn actuator, for example, will turn the valve’s mechanism 90 degrees, which is fully open.

It’s important to choose the electric valve actuator that runs on the right voltage to match your facility’s system. These systems vary depending on whether an operator uses alternating current (AC) or direct current (DC) power sources.

Some of the most popular voltage types are:

- 12 VAC

- 12 VDC

- 24 VAC

- 24 VDC

- 115 VAC

- 120 VAC

Along with the motor, actuators have other electrical components, including a limit switch, wiring, and gearing. All these parts are arranged in a compact, protective housing unit.

Torque Requirement for Electric Valve Actuators

Torque is the rotational force an actuator generates to close a rotational valve. Electric actuators can generate this force by transmitting it to the output shaft and then the valve stem. When pressure is applied to the valve stem, the valve’s orifice opens or closes.

Actuators have different levels of motor capacity (power) based on the torque they need to provide. It’s important to select actuators based on the breakaway torque a valve requires. The “breakaway torque” is how much power is needed to initiate the switch from a static open to a closed position or vice versa. It’s the highest level of torque required to operate the system.

Mounting Process

When you’re mounting electric valve actuators in place, use sturdy, industry-standard parts. Many actuators and mounting hardware use the ISO 5211 standards for connections, which ensures various brands and components work together seamlessly.

When you’re mounting electric valve actuators in place, use sturdy, industry-standard parts. Many actuators and mounting hardware use the ISO 5211 standards for connections, which ensures various brands and components work together seamlessly.

You’ll need at least three components for mounting:

- An output drive

- A stem to connect to the valve head

- A flange that mounts the actuator onto the valve

Various actuators require different types of flanges based on the torque and fasteners available.

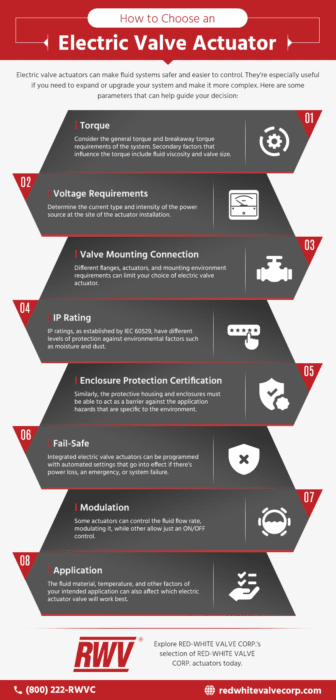

How to Choose an Electric Valve Actuator

Electric valve actuators can make fluid systems safer and easier to control. They’re especially useful if you need to expand or upgrade your system and make it more complex.

Electric valve actuators can make fluid systems safer and easier to control. They’re especially useful if you need to expand or upgrade your system and make it more complex.

Here are some parameters that can help guide your decision:

- Torque: Consider the general torque and breakaway torque requirements of the system. Secondary factors that influence the torque include fluid viscosity and valve size.

- Voltage Requirements: Determine the current type and intensity of the power source at the site of the actuator installation.

- Valve Mounting Connection: Different flanges, actuators, and mounting environment requirements can limit your choice of electric valve actuator.

- IP Rating: IP ratings, as established by IEC 60529, have different levels of protection against environmental factors such as moisture and dust.

- Enclosure Protection Certification: Similarly, the protective housing and enclosures must be able to act as a barrier against the application hazards that are specific to the environment.

- Fail-Safe: Integrated electric valve actuators can be programmed with automated settings that go into effect if there’s power loss, an emergency, or system failure.

- Modulation: Some actuators can control the fluid flow rate, modulating it, while other allow just a ON/OFF control.

- Application: The fluid material, temperature, and other factors of your intended application can also affect which electric actuator valve will work best.

Electric Actuator Valves From RED-WHITE VALVE CORP.

At RED-WHITE VALVE CORP., we serve a variety of industries by providing powerful, integrable electric valve actuators.

These industries include:

- Agriculture

- Food and beverage

- HVAC systems

- Oil and gas

- Paper pulp

- Power generation

- Wastewater treatment

For more details about our exceptional craftsmanship and specs, see our electric actuator product pages:

- Cutter-MOD Electric Actuator for Butterfly Valve

- Cutter-3PT Electric Actuator for Butterfly Valve

- Sloop2 Electric Actuator

- Vaurien I, Vaurien II Wax On/Off Actuator

- 24V Actuated Ball Valve