Industrial HVAC systems rely on valves for regulating temperature, flow rates, and pressure levels. It’s important to select the right one for your given application and function.

In this guide, you’ll learn about the different types of HVAC valves, their potential applications, and how to select the ideal valves for your HVAC system.

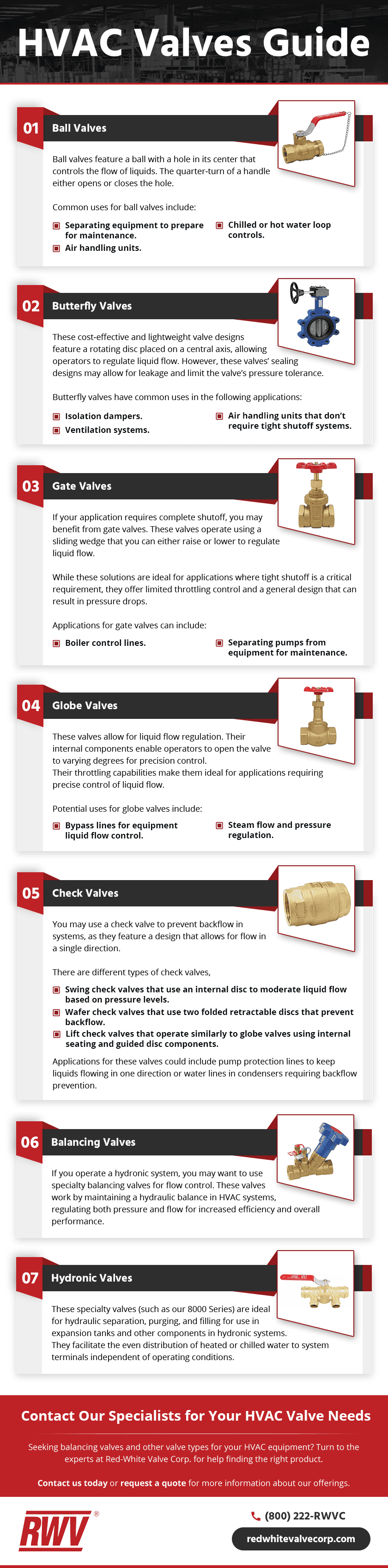

HVAC Valve Types

Choose from multiple valve types for HVAC applications, including:

Ball Valves

Ball valves feature a ball with a hole in its center that controls the flow of liquids. The quarter-turn of a handle either opens or closes the hole.

Common uses for ball valves include:

- Separating equipment to prepare for maintenance

- Chilled or hot water loop controls

- Air handling units

The following are some specific benefits of ball valves:

- A simple design that reduces maintenance requirements

- Minimal pressure drop using a full bore flow

- Complete cessation of flow through a tight shutoff

Butterfly Valves

These cost-effective and lightweight valve designs feature a rotating disc placed on a central axis, allowing operators to regulate liquid flow. However, these valves’ sealing designs may allow for leakage and limit the valve’s pressure tolerance.

Butterfly valves have common uses in the following applications:

- Isolation dampers

- Air handling units that don’t require tight shutoff systems

- Ventilation systems

Butterfly valves offer certain key benefits, such as:

- Cost-effectiveness

- Lightweight nature

- Easy installation

- Partial flow regulation

- Reliable on/off flow control

Gate Valves

If your application requires complete shutoff, you may benefit from gate valves. These valves operate using a sliding wedge that you can either raise or lower to regulate liquid flow.

While these solutions are ideal for applications where tight shutoff is a critical requirement, they offer limited throttling control and a general design that can result in pressure drops.

Applications for gate valves can include:

- Boiler control lines

- Separating pumps from equipment for maintenance

Gate valves offer the following benefits:

- Dependable on/off flow control

- Visual indicators of open and closed positions

Globe Valves

These valves allow for liquid flow regulation. Their internal components enable operators to open the valve to varying degrees for precision control.

Their throttling capabilities make them ideal for applications requiring precise control of liquid flow.

Potential uses for globe valves include:

- Bypass lines for equipment liquid flow control

- Steam flow and pressure regulation

These valves also come with the following benefits:

- A range of body materials based on liquid type

- Precision throttling and flow control

Check Valves

You may use a check valve to prevent backflow in systems, as they feature a design that allows for flow in a single direction. There are different types of check valves, including:

- swing check valves that use an internal disc to moderate liquid flow based on pressure levels

- wafer check valves that use two folded retractable discs that prevent backflow

- lift check valves that operate similarly to globe valves using internal seating and guided disc components

Applications for these valves could include pump protection lines to keep liquids flowing in one direction or water lines in condensers requiring backflow prevention.

Benefits of check valves include:

- Protection of equipment from damage

- Prevented backflow through automated regulation

Multiple valve types are available depending on installation and pressure level requirements.

Balancing Valves

If you operate a hydronic system, you may want to use specialty balancing valves for flow control. These valves work by maintaining a hydraulic balance in HVAC systems, regulating both pressure and flow for increased efficiency and overall performance.

Hydronic Valves

These specialty valves (such as our 8000 Series) are ideal for hydraulic separation, purging, and filling for use in expansion tanks and other components in hydronic systems. They facilitate the even distribution of heated or chilled water to system terminals independent of operating conditions.

Selecting the Right Valve for Your Industrial HVAC System

When choosing the ideal industrial HVAC valves, take the following into account:

- Pipe compatibility and size

- Temperature and pressure specifications

- Budgetary limitations

- Throttling, on/off, or other control requirements

- Maintenance needs and staff accessibility

Red-White Valve: Your Partner in Industrial HVAC Valve Solutions

If you need high-quality valves for your HVAC system, Red-White Valve Corp. manufactures some of the best solutions. These include a vast array of highly corrosion-resistant coil kit components such as:

- Pressure-independent control valves

- Automatic balancing valves

- Fixed-orifice manual balancing valves

- Unions

- Combination strainers

- Stainless steel hoses

One of our standout products is our 8000 Series Hydronic Installation Valve, a balancing valve that features corrosion-resistant DZR brass alloy construction, PTFE seating, and blow-out-proof stems to optimize performance in hydronic systems. These are ideal for use in HVAC, water return, and heat exchanger systems, facilitating efficient flow.

Using our hydronic valves, you can maintain comfortable temperatures in facilities with a cost-effective solution.

Contact Our Specialists for Your HVAC Valve Needs

Seeking balancing valves and other valve types for your HVAC equipment? Turn to the experts at Red-White Valve Corp. for help finding the right product.

Contact us today or request a quote for more information about our offerings.