Bronze and brass have similar compositions, appearances, and applications. They are both widely used copper alloy materials for valves, but they have different properties and price points. We’ll discuss these properties in more detail here, as well as their specific applications and advantages.

Bronze Valves

Bronze valves date back to the Romans during the first century B.C. Today, bronze is still primarily made from copper and tin, but modern additives typically include aluminum or manganese. Some bronze alloys can hold a polish if they contain nickel or lead, but generally bronze has a rough, porous finish.

Bronze valves can only be made by mold casting or machining cast ingots.

Brass Valves

Brass is a copper and zinc alloy. Brass valves are more versatile and malleable than bronze, and they can be made through casting, heat extrusion, forging, or cold drawing. The material naturally has a smooth finish that can save on finishing costs.

Brass is extremely corrosion-resistant, but prolonged exposure to chlorine or water can break down the zinc in the metal. Valves made of brass are ideal for natural gas and potable water applications.

Applications of Bronze Valves vs Brass Valves

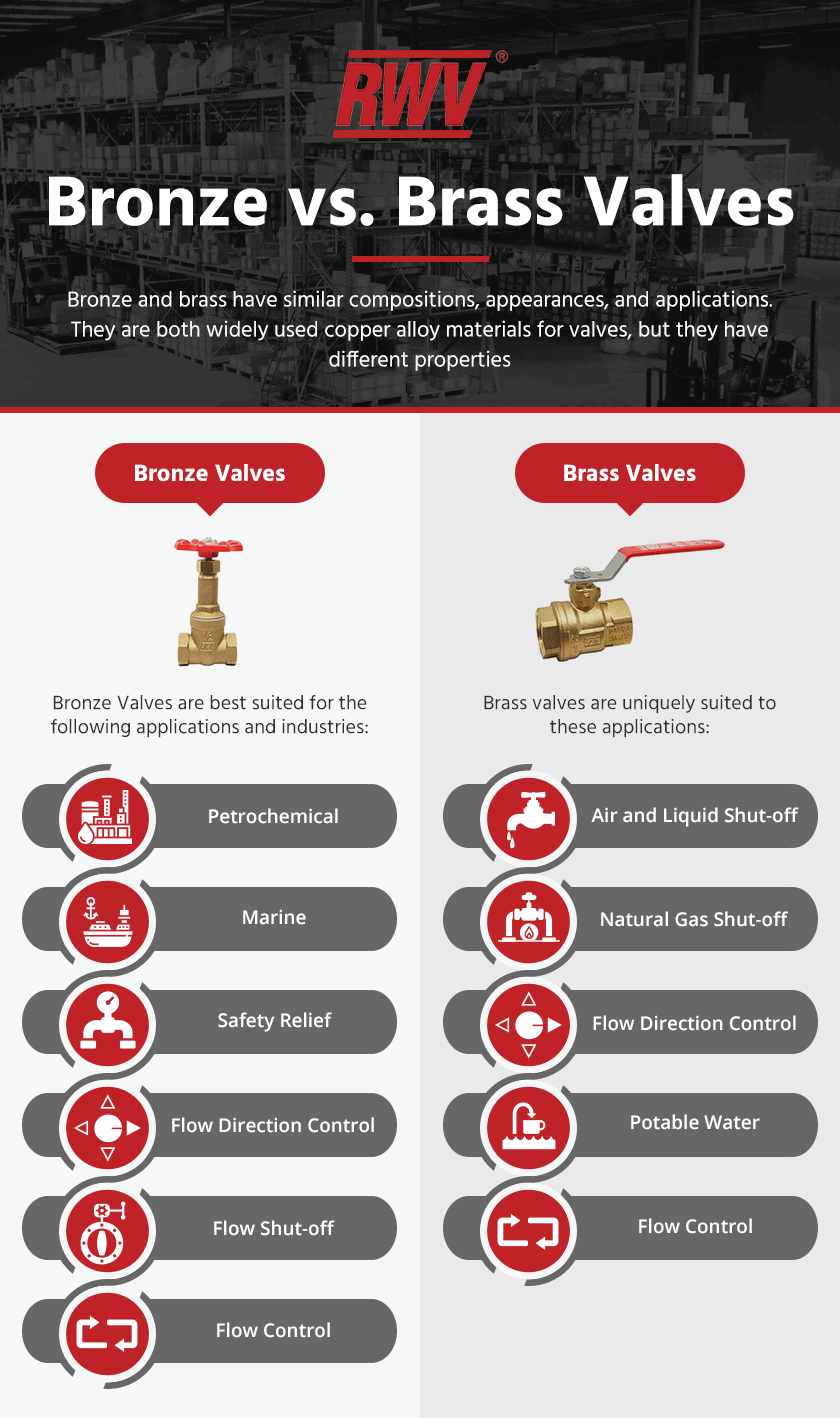

Because of their specific properties, bronze valves are best suited for the following applications and industries:

- Petrochemical

- Marine

- Safety relief

- Flow direction control

- Flow shut-off

- Flow Control

Brass valves are uniquely suited to these applications:

- Air and liquid shut-off

- Natural gas shut-off

- Flow direction control

- Potable water

- Flow Control

Advantages of DZR Brass vs. Yellow Brass Valves

DZR brass, or dezincification-resistant brass, refers to brass with particular elements that resist the removal of zinc by water. With non-DZR brass, continuous water flow could leave behind a weak and porous copper structure. DZR brass is ideal for pipes, fittings, and valves for potable water, or high-pressure water situations, such as waterworks.

DZR brass is formulated through a heat treatment process to resist dezincification and increase strength. In contrast, ordinary yellow brass water valves can corrode quickly. They are generally cheaper and easier to machine.. DZR brass valves are superior because of their higher copper content and lower lead and zinc content. The longevity benefits of DZR brass far outweigh any financial savings from using yellow brass valves.

Valves from RED-WHITE VALVE CORP.

With these properties of brass and bronze valves in mind, you can make a more informed decision for your valve application. RED-WHITE VALVE CORP. has provided top-notch service to the plumbing, commercial, HVAC, and industrial markets since 1971. We offer a vast selection of products, including standard valves and lead-free valves. Contact us for information or to start your project.